Mike figured out you can use other holes on the back wheels, not just the large threaded one, to move the suspension parts closer to the RC car body. He let me do the rest, which was tough. You have to keep strong pressure on the screw so you don't strip it, and keep it as straight as you can. It's not meant to be the primary spot for the screws, but can be used.

Next, Mike used his mini cut off saw to cut the brass tube into smaller pieces. He measured the rods and cut the brass tube to size.

Next was slipping the brass tubes over the rods, putting the end parts back on, and screwing the suspension parts back in.

During some test driving, a tiny part that I believe is called a wheel pin was temporarily lost. This kept one of the back wheels from working properly, messing with the rear wheel drive, which was due to the missing pin and the need to tighten the wheels.

Whoever owned this Traxxas before me switched the plugs that connect the motor and ESC, so Mike showed me how to switch them. Unsure why, but it turns out this is an easy fix.

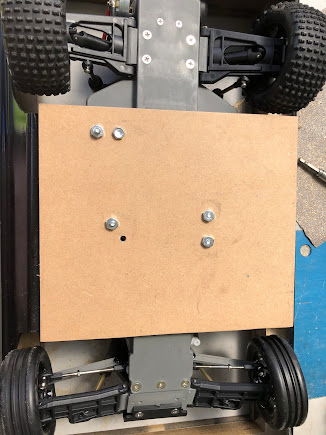

After all this, the bottom shell drove well with both frame parts in. I put the top shell on (a small increase in weight), and did more successful test drives. It. looks great even without details, but there's still more work to be done. A successful breakthrough and lots of progress thanks to Mike!

No comments:

Post a Comment